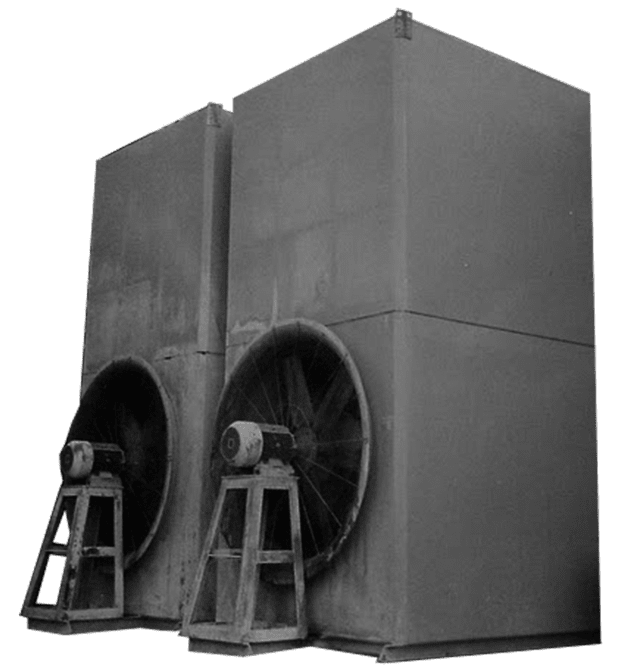

TCX SERIES

Centrifugal Cooling Towers

Equipped with centrifugal fans at the base and on the dry air side. They can be mounted inside as a fallback solution. A good option for Air Conditioning Installations or when low acoustic levels are required. Easy assembly of Acoustic Attenuators for air intake and discharge.

76 Models with nominal capacities from 88 to 6207 kW

TCL SERIES

Low Profile Cooling Towers

Equipped with centrifugal fans at the base and on the dry air side. Can be installed indoors as well. This is a good option for Air Conditioning installations and for environments that require low acoustic levels. Allows easy assembly of Sound Attenuators at the inlet/outlet air channels.

31 Models with nominal capacities from 299 to 1674 kW.

TLA SERIES

Axial Cooling Towers

Equipped with axial fans and constructed in Fiberglass reinforced polyester (FRP), screws and profils in Stainless Steel AISI 304 or UNIVAC Corrosion Protection System. Due to its low electrical power and resistance to corrosion, this is a good option for cooling in industrial environments.

29 Models with nominal capacities from 54 to 862 kW

TA SERIES

Axial Cooling Towers

Equipped with axial fan and constructed in Fiberglass reinforced polyester (FRP), screws and profiles in Stainless Steel AISI 304 or UNIVAC Corrosion Protection System. Due to its low electrical power and resistance to corrosion, this is a good option for cooling in industrial environments.

103 Models with nominal capacities from 263 to 5860 kW.

TMW - INOX SERIES

STAINLESS STEEL TMW SERIES

Industrial Cooling Towers

Equipped with axial fan and constructed in Stainless Steel AISI 304 (or 316) and fiberglass reinforced polyester (FRP). Suitable for cooling in industrial environemnts with large water flow. Can be configured in accordance with the requirements of the client: temperature class, degree of dirt and water corrosion and desired acoustic levels. Multi-cellular and good integration in industrial architectures.

114 Models with nominal capacities from 2125 to 71625 kW.

TMK - FRP SERIES

Large Industrial Cooling Towers

Equipped with axial fans and constructed with FRP pultruded profiles. Suitable for the cooling of large flows of water in industrial environments. High corrosion resistance. Can be configured in accordance with customer requirements: temperature class, degree of dirt and water corrosion and desired sound levels. Multi-cellular and good integration in industrial architectures.

12 Models with nominal capacities from 115 to 6048 m3/h per cell.

TAS SERIES

AS SERIES

Silent Axial Cooling Towers

Equipped with Axial Fans and manufactured in fiberglass reinforced polyester (FRP), screws and profiles in stainless steel or UNIVAC System.

THREE STRONG POINTS:

1 - STOP TO CORROSION - LONG LIFE

2 - LOW ACOUSTIC LEVEL

3 - LOW ENERGY CONSUMPTION

Easy maintenance and access to the interior of the Tower and to all components. A good option for AIR CONDITIONING and INDUSTRIAL PROCESSES.

118 Models with nominal capacities from 40 to 12.072 kW

SOUND ATTENUATORS

The acoustic level tunning process of our Evaporative Cooling Units requires an evaluation of acoustical, thermal and cost factors. UNICLIMA can perform this evaluation and propose the appropriate changes to achieve the objectives without sacrificing thermal performance. The Sound Attenuators are designed and manufactured by UNICLIMA. We provide accoustic attenuators for centrifugal fan units (TCX - TCL - ACX - ACL - CCX - CLC) and axial fan units (TLA - TA - ALA - AMA - CLA - CGA)

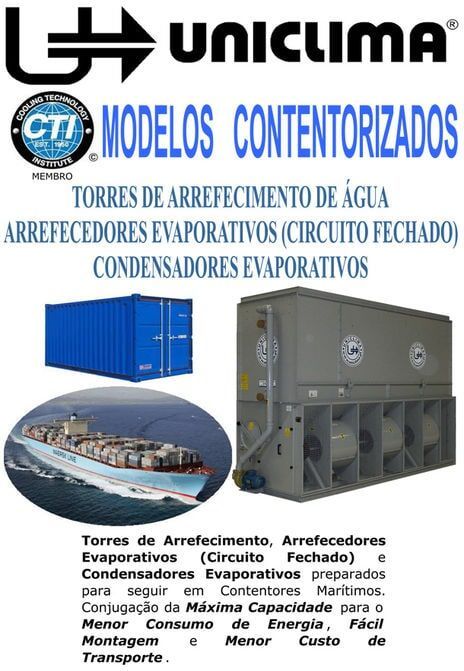

CONTAINERIZED

Containerized for sea

UNIVAC CORROSION PROTECTION SYSTEM

UNICLIMA developed and introduced in 1996 a UNIVAC SYSTEM. This system is not only a surface treatment, but also provides superior corrosion protection. The UNIVAC SYSTEM extends equipment life and provides a lower cost solution for cases where the equipment has to work in poor water quality, environmental considerations or equipment location. It is notable its resistance to salt spray, chemicals, abrasion, impact, ultraviolet radiation (sun) and thermal shock.

The

UNIVAC SYSTEM has the following proceeding:

1) Galvanized steel sheets and coated on both sides with Thermosetting Powder (Polyester Silicon Type),

2) Tightening of all components with screws and nut in stainless, avoiding this way the drilling of the panels after the Treatment of Surface with drills or self-threaded screws.

3) Use of PVC (Polyvinyl chloride) in Drift Eliminators, Water Distribution System, Fill, Tubular Connection, etc.

The combination of these three basic procedures with other small details define UNIVAC SYSTEM which provides a final product with the purpose of evaporative cooling water of high quality.